Executive Summary

This “Opportunity” is specific to developing the concept to facilitate Hemps potential. As well as applying for Provisional Patents. We then begin marketing!

The Problem

Since the passing of the 2018 Farm Bill legalizing the commercial cultivation and production of industrial hemp, serious problems have surfaced that are holding back the emerging hemp industry. Among them are harvesting, processing, and scalable warehousing. For example, outdated decorticators are still predominantly used at the field level to produce fiber and hurd from raw industrial hemp. The most significant problem with this processing strategy is waste and today’s equipment and management techniques leave up to an estimated 67% of the crop in the field. Another drawback is quality. Existing decorticator technology is unable to produce the high-quality end-user fiber that is needed to replace, for example nonrenewable building materials like fiberglass and steel. Furthermore, existing decorticators are unable to process industrial hemp on the scale necessary to meet the demand for industrial hemp manufacturing.

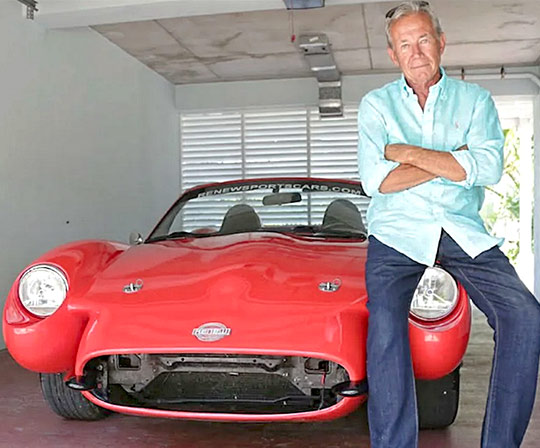

Bruce M. Dietzen, creator & founder of “Renew” the Hemp Sports Car, stated personally to Harold Stanislawski, of AURI and Jane Burnes Leverenz.

“There is a tremendous shortage of quality hemp fibers to make automotive parts and building materials to replace fiberglass and steel, and to produce textiles. What REGEN is developing is the most important project anywhere attempting to remedy this shortage.”

Please see Bruce Dietzen & Jay Leno on YouTube for more information.

The Bottleneck is Outdated Technology

Despite the renewed interest in industrial hemp production and growing demand for hemp-based products, there is a bottleneck in the hemp supply chain starting at the cultivation stage and extending to processing. This bottleneck is holding industrial hemp back from fulfilling its commercial potential.

Outdated harvesting and processing technology has not advanced much since industrial hemp was made illegal in 1937. This outdated technology also creates logistical challenges between cultivation, harvesting, and processing. Furthermore, the current technology does not allow for the quality control needed to produce the high-quality fiber and other products from industrial hemp that are demanded by end-users.

THE BIG IDEA

The Solution

REGEN is creating and providing needed infrastructure and scalability to the hemp industry, which we believe will generate confidence for both farmers and manufacturers. REGEN intends to create the new Supply Chain. REGEN Industrial Hemp USA’s multiple industrial designs of proprietary equipment and scalable processing is intended to launch the hemp industry to an entirely new level. The consumer market in turn will be ready and waiting for high-quality and sustainable hemp products to roll off the assembly line.

REGEN Industrial Hemp USA has positioned itself to facilitate industrial hemp by re-inventing industrial hemp harvesting, processing, and warehousing.

Harvesting: With REGEN’s combine, all parts of the industrial hemp plant are harvested for processing, dramatically reducing the common problem of field crop loss. We intend to achieve this through seed selection, new harvesting methods and newly developed equipment, which together provides more collectible crop volume.

Processing: Newly designed REGEN Decorticators & Driers, using enhanced technology, implemented in a fully automated processing plant moves the crop from field to indoor processing. This technology aims to create a higher standard of quality grade end-user goods for manufacturing.

Warehousing: REGEN’s concept encompasses all aspects of crop handling including preparing, processing, and wholesale warehousing for full distribution of all industrial hemp by-products. Processing will be done year-round with grade-specific products for manufacturers.

Technology Advantages

REGEN’s founder and CEO, Jane Burnes Leverenz, is intimately involved in the national hemp industry and, to her knowledge, REGEN Decorticators are the first decorticators incorporating Artificial Intelligence (AI) using technology confirmed with Dr. Chad Ulven, the Interim Chair of the engineering department of North Dakota State University. It will process industrial hemp stocks indoors in a controlled environment, reducing the loss in quantity and quality associated with other processing techniques. Most significantly, we have developed technology that changes the way the stalks are retted. Currently, retting is done with an acid bath or through field curing where loss is unavoidable. We believe that our 2 decorticators & advanced Multiuse Dryer technology is more efficient as well as environmentally friendly because retting is carried out to the stalks mechanically. The fiber produced is soft, pliant, adhesive and in its unimpaired natural state and suitable for weaving or our tensile fiber for replacement steel, replacement fiberglass, replacement rebar & Hemp Wood.

Another advancement in current technology is how the hurd and fiber are separated. Departing from manual outdoor labor in current approaches, the hurd is collected during processing. We believe that ours is the first decorticator capable of consistently meeting the demand for high-quality clean end-user goods. Vehicle body part manufacturers and other end-users demand fibers longer than the three-foot fibers produced by existing decorticators.

The REGEN Tensile Fiber Decorticator is designed to produce fibers that are equal in length to the stalks that are put into the machine (6-15 feet). In addition, no further fiber processing is required. It has been predicted that “hemp fiber will become the most relevant part of the hemp plant, and the most valuable of its outputs”.

A main competitive edge of the REGEN Decorticator is its scalability. Because it has been designed and is produced in 10-foot sections it can accommodate hemp processing facilities of a variety of sizes. A small processor could use a 10-foot section while the largest processor can combine up to ten sections to process up to 250 tons of industrial hemp per 8-hour workday.

Our REGEN Warehouse has been developed to provide a scalable size plant designed with two prep sites for our REGEN Multiuse Dryer and year-round stock processing. Our two-story design gives us a space to store the crop waiting for processing and keeping its quality. The REGEN Industrial Gravity Handler is designed to deliver quality stocks directly into the REGEN Decorticator, #1 for Textiles spin weave ready, #2 for Tensile-Strong Fibers.

REGEN’s goal is to revolutionize how industrial hemp is harvested, processed and warehoused in a controlled environment that enables greater quality control, to consistently achieve different grades for different purposes. In addition, the scalability of our processing equipment and warehouse has been developed to supply the growing end-user markets with commercial quantities of industrial hemp.

OPPORTUNITY SIZE

There is a substantial need for a third rotation crop other than corn and soybeans. According to the last census of the National Agricultural Statistics Service the United States had 531 million crop acres in 2021 “Frontier Data” and if 33% of the crop land in the United States is used for growing industrial hemp then up to 177 million acres could be used for growing industrial hemp. We anticipate that our full capacity REGEN Max Decorticator will be able to process 10,000 to 18,000 acres of industrial hemp. Based on a potential 177 million crop acres, and with an anticipated price of $25-$30 million per REGEN Max decorticator, 100ft bed, our total addressable market is potentially more than $550 billion just for the Textile Decorticater.

Thank You for this opportunity to share the core elements of this evolving Company.

It has a very powerful impact on the future of most manufacturing industries plus impacting the results of the process. Less input, more output. Less impact on resources which are dwindling.

Using Industrial Hemp is Life Restorative. Improved in Every way!

Please contact for further information.

A Pleasure.

Sincerely,

Jane Burnes Leverenz, CEO & Founder

REGEN Industrial Hemp USA

proprietary equipment for harvesting, processing, and warehousing